Professional Concrete Leveling & Stabilization

At Allstate Pro Level, we specialize in concrete leveling for residential and commercial properties in East Texas. Our team assesses the underlying causes of settlement—often related to expansive clay soils and moisture changes—and delivers precise, effective solutions with minimal disruption to your property.

What Causes Concrete to Heave? Identifying Potential Root Causes

Concrete heave occurs when upward pressure from below lifts slabs or surfaces, resulting in unevenness, cracks, or raised sections. In East Texas, this is most commonly tied to the region’s expansive clay soils, which expand significantly when saturated with moisture. Understanding the primary causes helps determine whether leveling or stabilization is appropriate.

Expansive Clay Soil & Moisture Changes

East Texas clay soils absorb water from heavy rainfall, poor drainage, plumbing leaks, or over-irrigation. As the soil swells, it exerts upward force on concrete slabs, driveways, patios, or sidewalks—leading to heaving and potential cracking.

Freeze-Thaw Cycles (Less Common in Most Areas)

In northern parts of East Texas with occasional hard freezes, water in the soil freezes and expands, pushing concrete upward. Thawing causes contraction, contributing to repeated movement over time.

Tree Root Systems

Large tree roots growing beneath or near concrete can displace soil or create localized pressure as they expand. While roots more often cause settlement by drying soil, they can contribute to uneven heaving in some cases.

Soil Settlement

Over time, the soil under your patio can sink or settle, creating empty gaps. When the concrete is left with no support from the ground, it can easily crack under its own weight.

Soil Erosion or Runoff

Water flowing from sprinklers, downspouts, or grading issues can wash away supporting soil, creating voids or instability that allows upward shifts in adjacent areas.

Improper Installation or Compaction

Concrete placed on poorly compacted or inadequately prepared soil may experience differential movement as underlying conditions change over time.

Identifying the specific cause requires a professional assessment to evaluate soil conditions, drainage patterns, and structural movement. At Allstate Pro Level, we conduct thorough on-site reviews to determine whether polyurethane foam lifting (polylifting) or additional stabilization is needed. This targeted approach addresses the root issue with minimal disruption, restoring level alignment and long-term stability.

Concrete Lifting in Action

Sunken or uneven concrete is more than an eyesore; it’s a potential liability. Our Precision Lift system corrects this issue at its source. We use a specialized two-part polyurethane resin to accurately lift and stabilize the concrete, restoring a level and safe surface. This modern approach saves you considerable time and money compared to traditional demolition and replacement.

What's the Difference

At Allstate Pro Level, we rely on the Poly-lifting method because it offers superior performance, long-term reliability, and minimal disruption. This technique uses a high-density polyurethane foam that weighs just 2 pounds per cubic foot—significantly lighter than the slurry mixture used in traditional mudjacking. Once injected beneath the slab, this two-part polymer expands up to 15 times its original volume, filling voids and lifting the concrete with precision.

Polyurethane Lifting Foam

Material Composition: Employs a high-density, structural-grade polymer foam created by combining two liquid components. This material is engineered specifically for lifting and stabilization.

Installation Process: Requires only small, 5/8-inch injection holes (about the size of a dime). The process is clean, efficient, and far less invasive to the existing concrete.

Curing Time & Usability: The foam cures and reaches 90% of its final strength within 15 to 30 minutes, allowing the area to be used almost immediately.

Durability and Longevity: The polymer foam is an inert, waterproof material that will not shrink, erode, or break down. It provides a permanent, stable solution.

Precision and Control: The foam’s controlled expansion allows for a highly precise and incremental lift, ensuring a more accurate and even final result.

.

mudjacking

Material Composition: Utilizes a heavy slurry composed of a mixture of soil, sand, cement, and water. The exact composition can vary.

Installation Process: Requires drilling large holes, typically 1.5 to 2 inches in diameter, to pump the heavy slurry beneath the slab. The process can be messy.

Curing Time & Usability: The material can take 24 to 72 hours to cure before the surface can bear heavy loads, such as a vehicle.

Durability and Longevity: The organic slurry material can shrink as it dries and is susceptible to erosion and washout over time, potentially requiring the repair to be redone.

Precision and Control: Lifting is done with hydraulic pressure, which can be difficult to control precisely, sometimes resulting in an uneven lift.

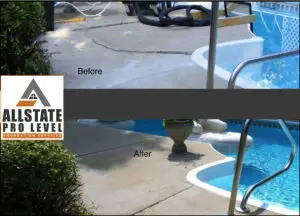

Before and After

These transformations showcase our commitment to restoring structural integrity. Each project, from foundation piering to concrete leveling, represents a complex problem solved and peace of mind restored for a homeowner. See the difference our expertise can make for your property.

Do You Have More Questions?

We’d love to hear from you!! Fill out the form below and someone from our team will reach out right away. Or you can call us at